Why do EV battery packs need a cooling system?

There are a bunch of inter-related reasons to control the temperature of an EV’s battery pack. While cooling is crucial, warming can also be important.

The safety, service life, storage capacity and charging speed of a lithium-ion battery pack are all temperature dependent, so it’s really desirable to keep its cells working in a fairly tight range between about 20 and 40 degrees C.

What happens if you don’t? Good question…

Fire is the headline hazard. Every owner of a mobile phone or laptop computer will have noticed their device gets warm, maybe even hot, when it’s being charged. EVs are no different, but there’s a lot more heat to deal with.

How much more? Here’s a useful comparison. What you’re reading right now is being written on a MacBook Pro. My laptop’s bottom gets quite toasty when its battery is being charged. The battery pack of last EV I drove, a Leaf e+, stores roughly 1000 times more energy.

Batteries and battery packs also heat up when continually discharging at high rates.

Letting the heat build up is dangerous. Though the threshold temperature varies somewhat among the different lithium-ion cell chemistries, at around 140 degrees C a process called “thermal runaway” occurs.

What this means is that the cell gets hotter and hotter, and nothing can be done to stop the process. This can lead to the cell catching fire or bursting.

Disaster! Which is why automotive battery packs combine sensors and software into a complex management system to constantly monitor temperature and other key operational parameters.

There are other reasons why heat is undesirable in a battery pack. Cell aging processes are accelerated by heat, so temperature control is a key factor for ensuring the battery pack has the longest possible useful life.

Battery pack temperature also influences charging speed. Remember that the cells in the pack heat up when they’re being charged. Serious amounts of heat can be generated when charging quickly, as at a DC fast charger. Without a cooling system to carry this heat away, the only way to protect the battery pack is to reduce the charging rate; that’s also why the car will adjust its charging rate depending on the temperature and state of charge (SOC).

There are consequences if a battery pack gets too cold, too. Low temperatures greatly reduce the amount of energy a lithium-ion cell can store. This, in turn, means a lot less driving range.

Thermal management is what engineers call keeping the battery pack in its comfort zone. There are different ways to ensure the cells remain in the just-right range between too hot and too cold.

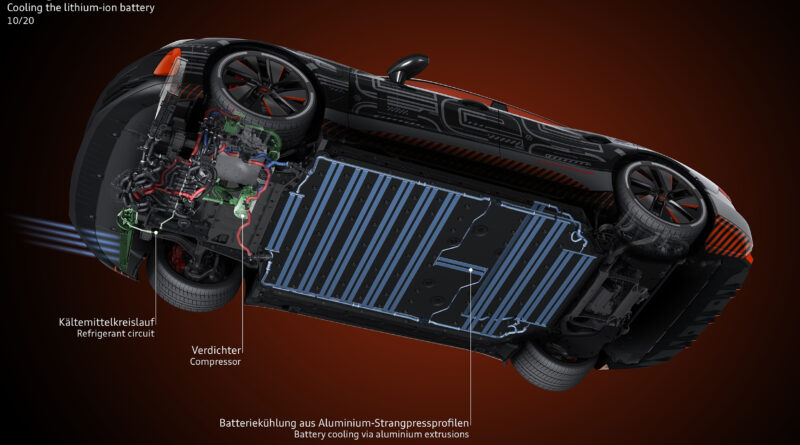

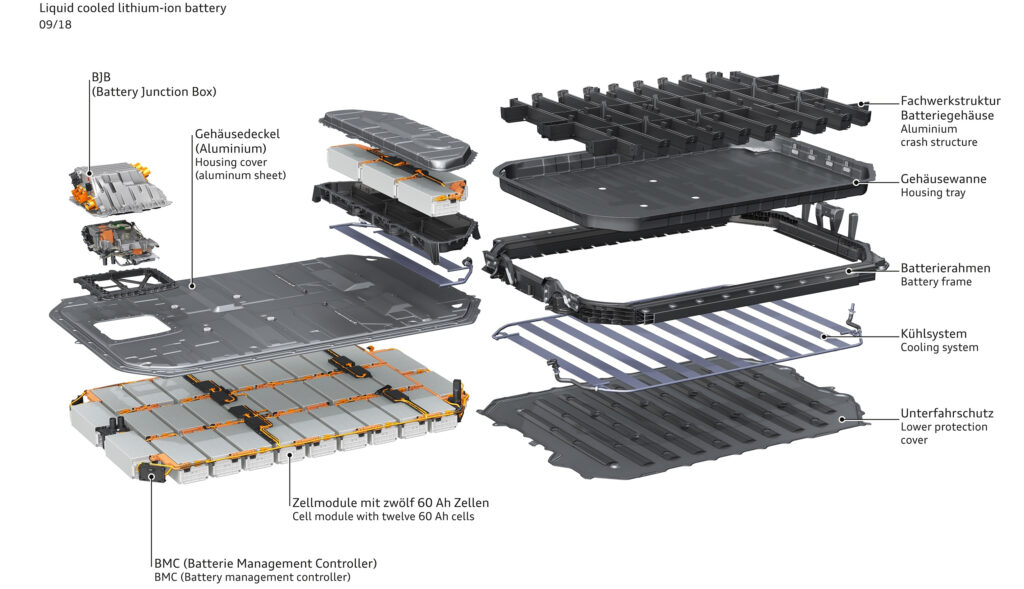

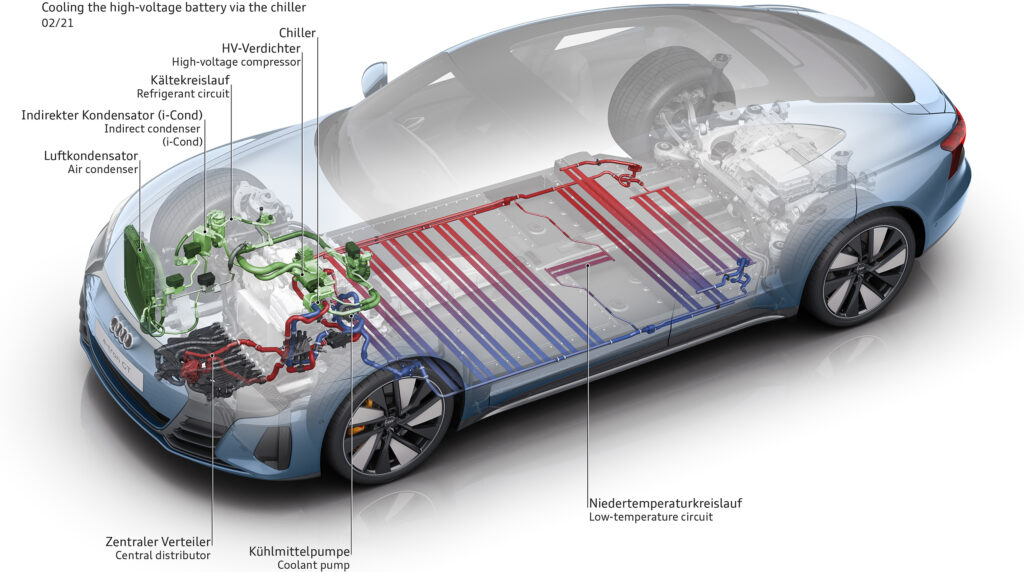

Liquid cooling is the most popular solution with EV manufacturers. This involves pumping coolant (which needs to be replaced through regular servicing) through pipes or plates built into the battery pack, where heat is collected, and then through a radiator, where the heat is dissipated.

Refrigerant-based systems are sometimes used, but rarely. These work on the same principle as a car’s air-conditioning system, by circulating a refrigerant gas through pipes around the battery pack, a radiator and a compressor. And like reverse-cycle air-con, they can also be used to heat the pack, something that’s a bit more difficult with other systems.

Air cooling is simpler and cheaper, but because air cannot carry as much heat as a liquid coolant it’s also the least effective. The most basic set-ups simply let the air circulate around or through the battery pack. Adding a fan to increase flow improves effectiveness, as does using the air-con system to chill air before puffing it through the pack.

The Nissan Leaf is the best-known example of an EV with an air-cooled battery pack, but the Renault Zoe is another.

Early versions of the big-selling Nissan proved prone to premature battery pack aging in hot climates. Some owners also found DC fast-charging rates could be slowed way down when the battery pack temperature rose high enough to ring management system alarm bells.

Although the battery pack of the latest Leaf e+ has so far been trouble-free, Nissan’s earlier problems mean that air-cooled battery packs have a bad reputation with the EV community.

READ MORE: See all our EV advice and FAQ