GM reveals Ultium e-motor secrets

General Motors has revealed more details of the e-motors and power electronics that will be a critical part of its shift to an electric vehicle future.

Branded Ultium like the battery packs that work with them and the underpinning GM EV vehicle architecture, the new-generation e-motors will debut in the 2022 GMC Hummer ute, followed quickly by the Cadillac Lyriq.

GM has committed to debuting 30 EVs by 2025 and we know among them we’ll see an electric Chevrolet Silverado and a GMC pick-up.

UPDATE: Chevrolet Silverado EV to break cover early in 2022; focus on tech

EXCLUSIVE REPORT: EV ute overload: Every electric pickup coming soon

Ultium will also underpin two EVs being developed with Honda and its luxury brand Acura.

GM has rolled out the Ultium e-motor specs as controversy continues in the USA about fiery battery fires in the Chevrolet Bolt.

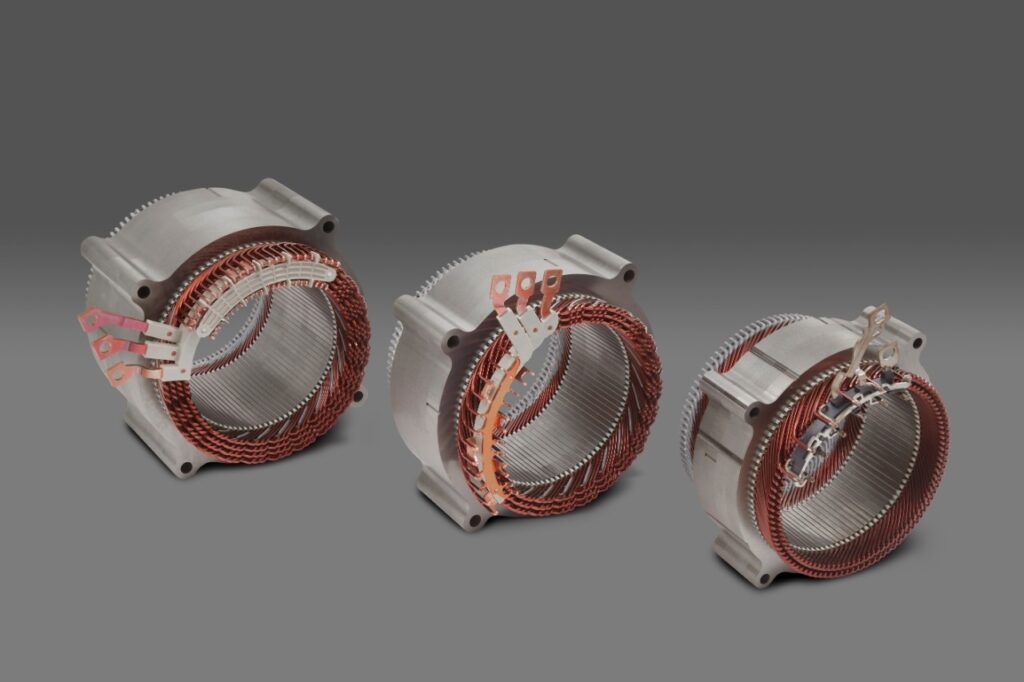

There are three e-motors in the Ultium line-up; a 180-kilowatt front-drive motor, 255kW rear- and front-drive motor and 62kW all-wheel drive assist motor.

The 180kW and 255kW units are permanent magnet motors designed with the aim of minimising reliance on heavy rare earth materials while the 62kW unit is an induction motor. As part of its EV transformation GM has already committed to using less cobalt in its Ultium batteries, part of a plan to reduce costs.

As many as three electric motors can be used in one EV – variations of the 2022 GMC Hummer EV will feature three separate 255kW motors, yielding a GM-estimated output of 1000 horsepower (746kW).

They have been built as a scalable family, sharing design principles as well as similar tooling and manufacturing strategies. They share a common stator and are designed to use common winding tools, common magnets, and common hairpins.

All up, GM has five motor layouts and 19 different battery and drive combinations ready to go.

Software is critical to the operation of the Ultium e-motors and power electronics components and development has been handled in-house by GM engineers.

The team used computer-assisted and virtual engineering to quickly, safely and affordable to develop and refine e-motor software management.

For instance, artificial intelligence and machine learning helped determine the most efficient ways to distribute torque in the Hummer’s three-motor to ensure it worked off-road, on public streets and delivered a three second 0-60mph (96km) time in Watts to Freedom mode.

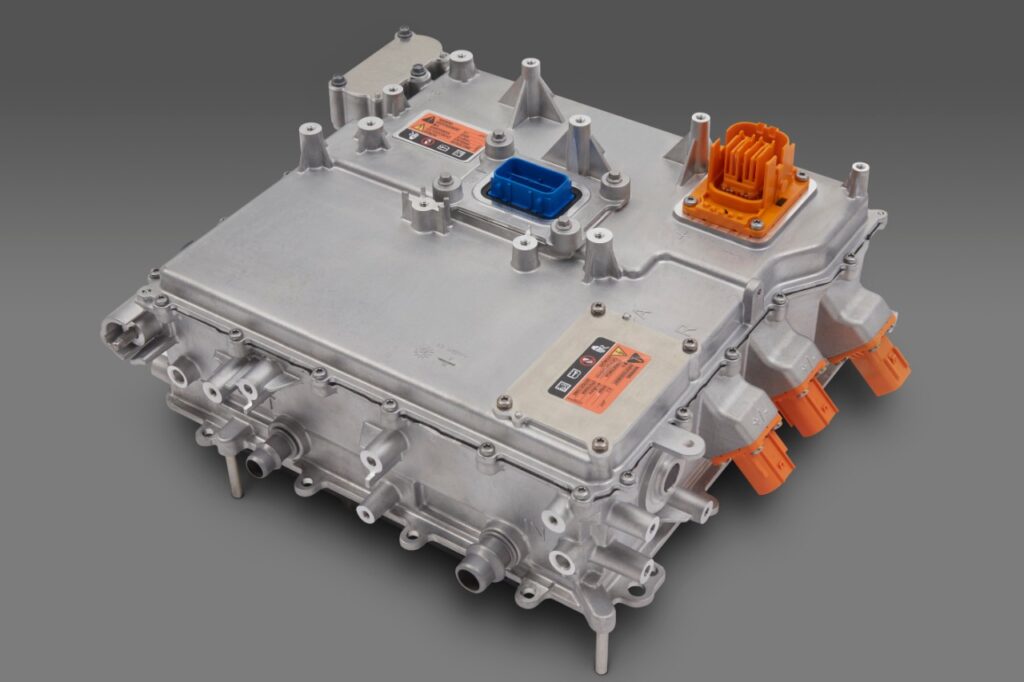

Software development encompassed key power electronics components such as the inverter, which converts DC voltage from the battery to AC voltage to power the motor.

The inverter and other power electronics, like the accessory power module and onboard charging module, reside outside of the drive units on GM’s current EVs. In Ultium-based vehicles, they will be integrated directly into Ultium Drive units, reducing cost and manufacturing complexity.

Some power electronics will have as much as 50 per cent less mass and volume than today’s GM equivalents, with as much as 25 per cent more capability.

“Twenty years of electric drive system development and more than 100 years of high-volume vehicle engineering are helping GM pivot quickly from conventional vehicles to EVs,” said GM president Mark Reuss.

“Our vertical integration in this space, encompassing both hardware and software, helps give us control over our own destiny and a significant competitive advantage.”