Australia is EV fantasy land … at least with manufacturing

Manufacturing EVs in Australia isn’t a dream… it’s a fantasy.

Among the world’s developed nations, Australia is possibly the most EV-phobic of all. This is the country where the Federal Government refuses to encourage people to buy EVs, State Governments propose special EV-specific taxes and some car makers are too timid to import EVs. So barely anyone buys EVs.

What established car maker or energetic entrepreneur in their right mind would choose to invest in making EVs in Australia?

Still, this doesn’t stop some people dreaming of turning Australia into some kind of plug-in paradise.

Why, for example, couldn’t the abandoned Holden factory on the outskirts of Adelaide be sparked back to life to produce EVs?

So now there are reports of a politician in South Australia busily penning a letter to Elon Musk, inviting him to begin making Teslas in his state. And if Musk has other things he’d rather do, like go live on Mars, there are plenty of others who might be interested in setting the production lines rolling again. In theory…

It’s only three years since the Holden plant built its last car, but this doesn’t mean it would be a simple job to set it to work again making EVs.

Few people really understand how a car factory works. One common misconception is that all of them are alike. Not true. Every car factory is designed to turn out a specific model or closely related family of models.

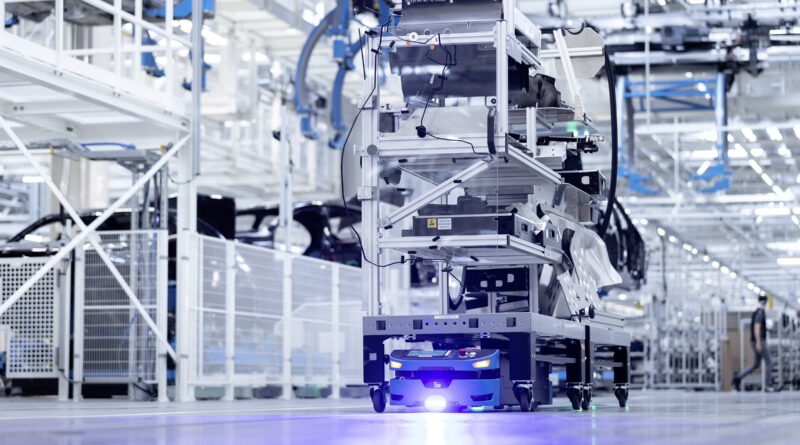

Cars aren’t all made the same way. A production line is an array of expensive machinery that’s been carefully specified, designed, organised and even spaced to build a specific car in an equally specific sequence.

It might be possible to modify some of the more versatile machinery, but much of the equipment will need to be either rearranged or replaced before the factory can produce a different car. And this is expensive. Very expensive indeed.

As a rough rule of thumb, when a car maker has $2 billion – a normal sort of number – to prepare a new car for market only half that amount will be spent to design, engineer, develop and test it. The other $1 billion will go on preparing the factory to make it.

So unless there’s someone out there who yearns to waste a fortune building an obsolete Commodore, the Holden factory at Elizabeth is basically a big shed filled mostly with scrap metal.

It looked like a pretty good shed the last time I saw it, but there’s one small problem… it’s in the wrong place.

Car makers tend to prefer to make cars where they sell cars. For obvious reasons. So you have to ask yourself about rumours and reports that BYD, the big Chinese EV manufacturer, would choose to build a factory in Australia.

China buys more cars, and more EVs, than any other country on the planet. The Australian car market is both small and EV-averse. But these aren’t the only reasons the chance of seeing a BYD factory built in Australia are, in my opinion, somewhere between nil and negligible.

Another thing most people don’t understand about the auto industry is that the brand that puts its badge on the finished product doesn’t actually produce most of the stuff needed to make the car.

Not only obvious things like tyres and windscreen wiper blades will be made by outside suppliers, but also costly and complex items like transmissions and brake systems. When the value analysis is done, you’ll discover that a car maker typically manufactures only around 25 percent of their product and buys the rest from suppliers.

In case you didn’t notice at the time, Australia waved goodbye to most of its network of automotive component suppliers when the Holden, Ford and Toyota factories in Adelaide and Melbourne closed.

Another concern for any prospective manufacturer of EVs in Australia is that there is no local producer of lithium-ion batteries, nor any sign of such an industry developing. While Australia has an abundance of all of the minerals and metals needed to make an EV battery pack, we simply dig ’em up and ship ’em elsewhere.

Lithium-ion battery packs are not only the single most expensive part of an EV, they’re also bulky and heavy. If you’re a car maker you want your batteries to come from next door, saving the considerable expense and logistical problems of shipping, not someplace thousands of kilometres away.

It’s a depressing picture, I know. Some of you may imagine that smart policies devised by the wisest and wiliest of our elected representatives in Canberra might change the situation, but I’m pessimistic about that, too.

Based on past and current performance they seem determined to continue proving to the world that Australia excels at making only two things; great big holes in the ground… and mistakes.