New family of affordable Teslas detailed: ‘multiple’ EVs coming as part of 20 million vehicle push

The long-hyped circa-$40,000 Tesla Model 2 didn’t break cover at the company’s investor day held at the Texas Gigafactory this morning. Nor did Tesla outline the rumoured radical updates to the Model 3 and Model Y.

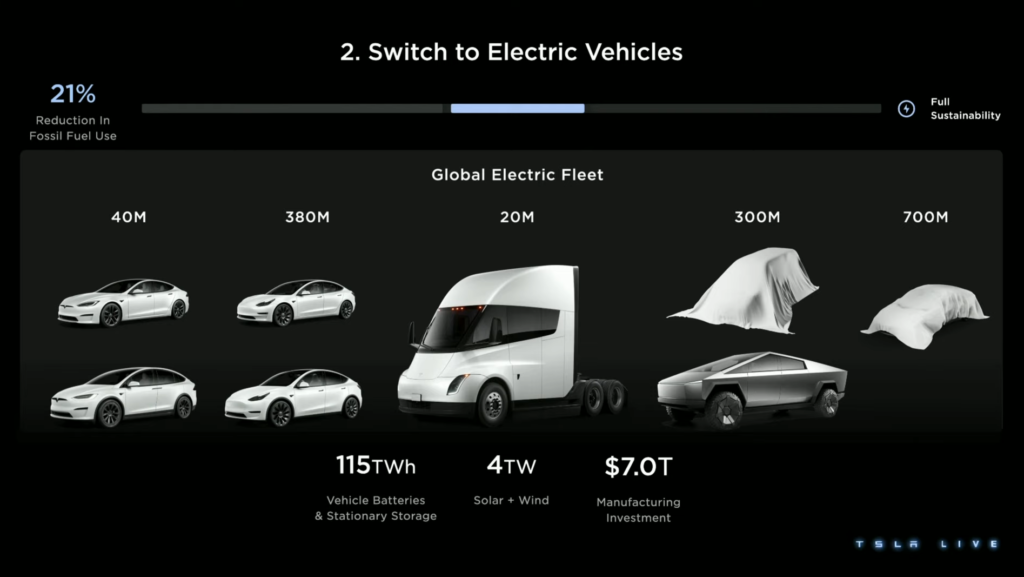

Instead, Tesla laid out the building blocks for a new family of more advanced and affordable models that will form the foundations for the brand as it strives to build 20 million cars annually by 2030 – in turn surging past traditional brands such as Toyota and Volkswagen.

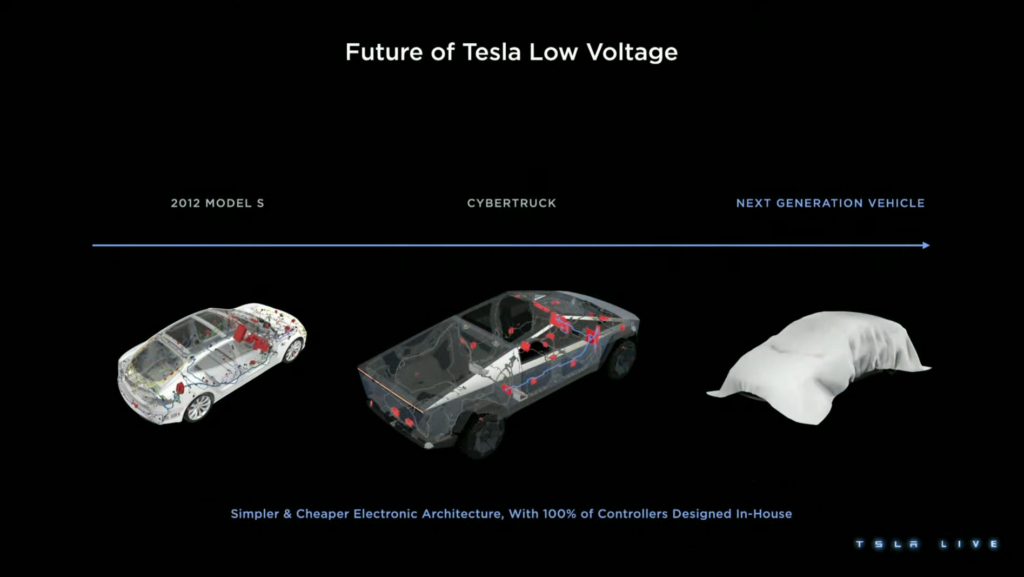

It also confirmed the radical Cybertruck electric ute would enter production late in 2023, in turn ushering in a new 48-volt electrical system for vehicle ancillaries such as infotainment, lights and ventilation – part of the push to improve efficiency and reduce weight.

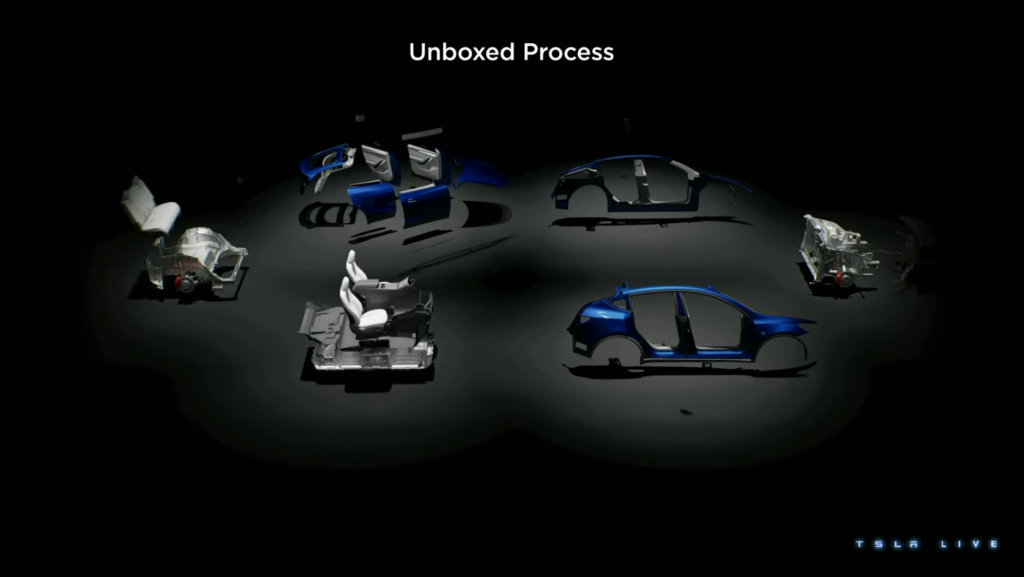

Key to the upcoming new Tesla models is a “new-gen” architecture inspired by the development of the Cybertruck. The new platform will also enable a radically different manufacturing process designed to dramatically reduce the cost of production.

Tesla CFO Zach Kirkhorn said that the cost of building a Model 3 and Y halved when compared with a Model S and X.

“The task here is to do it again,” he said of the upcoming new family of vehicles, of which the company said there would be “multiple” versions.

“As we improve affordability the number of people who have access to our products dramatically increases,” said Kirkhorn. “It enables an exponential growth in our volume with linear reductions in the cost of our products.”

Tesla CEO Elon Musk said Tesla demand was driven by affordability rather than desire – and that even a small reduction in the price of the vehicles could have a significant impact on how many people joined the queue to own one.

With the future products in the pipeline there’s a chance Tesla could further boost its growing sales.

As well as reducing manufacturing costs, Tesla said it planned to continue innovating to deliver better vehicles.

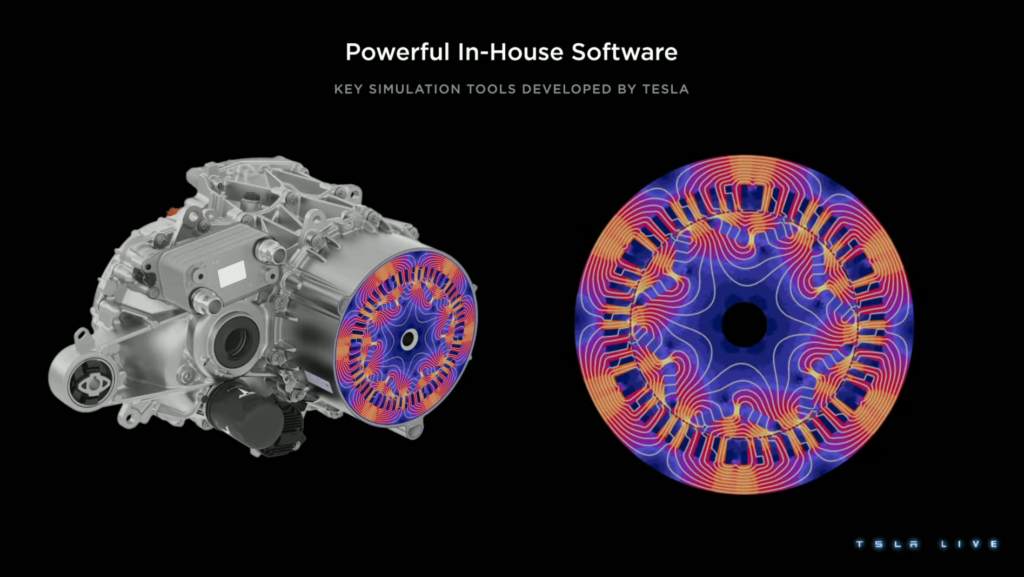

Battery packs and electric motors are at the core of that; Tesla says its next generation drivetrains are about US$1000 cheaper to manufacture than today’s vehicles.

The company will also continue innovating on software, in turn utilising data it sources from the connected nature of its vehicles.

Tesla says 85 percent of the electrical architecture in the Cybertruck will be designed and manufactured in-house – rather than sourced from suppliers, which is what most manufacturers do – and that with the new generation of vehicles that will increase to 100 percent.

But there were no new models to be seen, with Tesla instead showing cloaked silhouettes of upcoming vehicles and detailing how it plans to produce them more efficiently – and create more desirable vehicles.

However, Tesla did confirm it would build a new Gigafactory in Mexico, adding to the two US production lines (one in California and one in Texas), the one in Shanghai, China and the one near Berlin, Germany.

And, as a last minute surprise, Tesla gave a hint of how it could spread its brand into fast food.

Under the headline of “Can’t Forget To Do Cool S***” Tesla showed what looks like a futuristic Tesla diner with banks of chargers.