Hyundai unveils EV platform with over 500km range

Hyundai Motor Group, the parent of Hyundai, Kia and luxury brand Genesis, has unveiled the dedicated battery electric vehicle architecture that will play a key role in its plan to sell one million electrified vehicles by 2025.

Dubbed the Electric-Global Modular Platform (E-GMP), it was revealed online today during an ‘E-GMP Digital Discovery’ event.

A BEV based on E-GMP is capable of a maximum range of over 500km with a fully charged battery, according to the WLTP standatds. It can also high-speed charge up to 80 per cent in just 18 minutes and can add up to 100km of driving range in just five minutes.

From 2021, the E-GMP will underpin a range of dedicated new BEVs starting with the first model from the new Hyundai sub-brand, the IONIQ 5 (previewed as the Ioniq 45 concept) and the Kia CV.

By 2025 HMG plans to have released 23 BEV models and have sold more than one million of them. Eleven of those BEVs will be based on E-GMP, while 12 will be offered with both orthodox and electrified powertrains, such as the Kona electric.

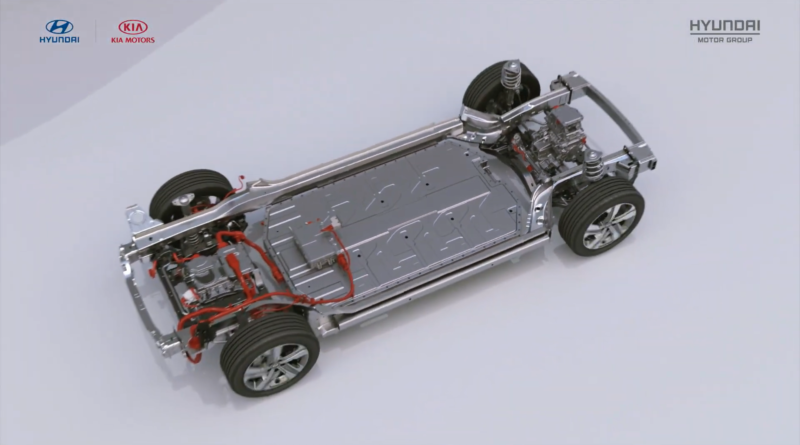

Designed exclusively for BEVs, HMG says E-GMP provides various advantages compared to its existing platforms, which have each been engineered predominantly to accommodate internal combustion engines.

Benefits include increased development flexibility, powerful driving performance, increased driving range, strengthened safety features, and more interior space for occupants and luggage.

“E-GMP is the culmination of years of research and development and brings together our most cutting-edge technologies. Our BEV line-up will evolve and be strengthened by this innovative new platform,” said Fayez Abdul Rahman, Senior Vice President of Vehicle Architecture Development Center for Hyundai Motor Group.

HMG says E-GMP reduces complexity through modularisation and standardisation, allowing rapid and flexible development of products which can be used across most vehicle segments, such as sedans, SUVs and CUVs.

High-performance models will be included in the roll-out. HMG claims they will be capable of accelerating from rest to 100km/h in less than 3.5 seconds and achieve a maximum speed of 260km/h.

HMG says E-GMP is engineered to offer improved cornering performance and driving stability at high speed due to optimal weight distribution, a low centre of gravity because of its battery pack position and the adoption of electric motors located in the space previously occupied by an engine.

A high-speed e-motor design, a five-link rear suspension system and a claimed world first integrated drive axle (IDA) – which combines wheel bearings with the drive shaft to transmit power to the wheels – enhance ride comfort and handling stability.

The platform secures battery safety through a support structure made of ultra-high strength steel. Hot-stamped steel components surround this structure for additional rigidity.

Collision energy can be absorbed efficiently thanks to energy-absorbent sections of the body and chassis, effective energy load paths, and a central section of the battery pack bound to the vehicle body.

By strengthening the structure of the load support section, located in front of the dashboard, engineers have been able to minimise collision energy to the power electric system and battery, HMG says.

As a skateboard design E-GMP maximises interior space through its battery pack mounted beneath the floor, long wheelbase, short front and rear overhangs, and slim cockpit module.

The battery pack sits between the front and rear wheel axles and will be the most power-dense system HMG says it has ever created. This is partly thanks to its enhanced cooling performance, a result of a new separate cooling block structure which helps make the battery pack more compact.

With energy density enhanced by around 10% compared to existing EV battery technology, the battery packs are lighter, can be mounted lower in the body, and liberate more cabin space.

All vehicles developed with the E-GMP platform use a standardised single type of battery module. This module is composed of pouch-type standard cells and can be packed in different quantities as required for each vehicle.

The E-GMP’s compact new power electric (PE) system consists of a motor, EV transmission and inverter. These three components are integrated into a single compact module.

HMG says this ensures powerful performance by raising the motor’s maximum speed by up to 70 per cent compared to existing motors. The high-speed motor is smaller than other motors while providing comparable performance, and it gives efficiencies in both space and weight.

The motor is controlled by the inverter power module, which adopts silicon carbide semiconductors. This motor can enhance system efficiency by up to three per cent, which means the vehicle can be driven for approximately five per cent longer on the same battery energy.

E-GMP relies on the rear wheels for propulsion., but customers will be able to choose all-wheel drive configurations vis an additional motor. The all-wheel drive system includes an EV transmission disconnector, which can switch between two-wheel and all-wheel drive modes.

E-GMP offers 800V/350kW DC fast-charging capability as standard and enables 400V charging without the need for additional components or adapters. The multi-charging system is a claimed “world’s first” patented technology which operates the motor and the inverter to boost 400V to 800V for stable charging compatibility.

HMG says the E-GMP’s newly developed Integrated Charging Control Unit (ICCU) represents an upgrade from existing On-Board Chargers (OBC), which typically only allow electricity to flow in a single direction from an external power source. The ICCU enables a new vehicle-to-load (V2L) function, which can additionally discharge energy from the vehicle battery without additional components.