Do electric cars have gearboxes?

No, not really.

The transmission of a conventional car is a complicated thing, but what an EV uses is really, really simple. The difference is huge.

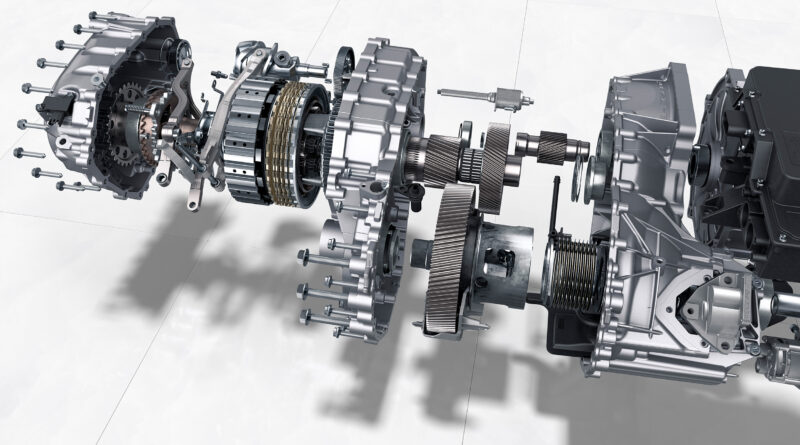

All ICE-powered vehicles, including plain and plug-in hybrids, require a multi-ratio transmission. These are costly, complex assemblies. Inside them are clutches, torque convertors, multiple sets of gears or, sometimes, belts and pulleys. In the case of an automatic, double-clutch or continuously-variable transmission, there will also be machinery, usually electro-hydraulic, to shift between gear ratios when told to do so by the car’s drivetrain management software.

Inside the transmission of nearly every EV on sale today – we’ll get to the exception in a moment – are two toothed cogs. And that’s it…

One of these is always bigger than the other. The smaller cog is attached to the output shaft of the EV’s electric motor. The larger cog is connected to to the driving wheels via shafts.

EV’s do not require any kind of a clutch between motor and wheels for two reasons. The first one is pretty obvious. Unlike an ICE-powered car, an EV’s motor doesn’t need to idle while it’s stationary.

The permanent connection between motor and wheels that the single-speed transmission of an EV provides also enables regenerative braking. This is what happens when the driver eases off the accelerator pedal or gently presses the brake pedal. Here the motor switches from sucking electricity to generating electricity, and the energy needed to do this slows the car.

This simplicity is possible because electric motors aren’t like ICEs. Electric motors produce strong torque from zero revs and so deliver brisk acceleration from standstill. They are designed to spin up to 10,000rpm or more, way faster than the typical ICE, and all of the rev range is usable.

Unless an EV is designed to hit an extremely high top speed, one gear is all that’s needed. Which brings us to the Porsche Taycan. It will reach a genuine 270km/h, proper fast-lane pace on a German autobahn. To do it the four-door coupe is fitted with a computer-controlled two-speed transmission on its rear axle.

In contrast, an ICE will have a usable rev range that’s only half as wide as an electric motor. And there are a bunch of good reasons why you want it to spin as slowly as possible while producing whatever power is needed at any moment; fuel consumption, engine wear and noise are all reduced.

Most ICE-powered cars today can do 110km/h in third gear, but no-one in their right mind would torture an engine by driving Sydney to Melbourne this way. With an electric motor, which has one moving part and minimal internal friction, there’s no disadvantage or problem with spinning fast for extended periods.

One gear is all they need to do it all…