Battery tech up-ended; huge range gains claimed

A UK start-up has literally tippeed orthodox battery pack design on its head and claimed huge range gains for electric vehicles as a result.

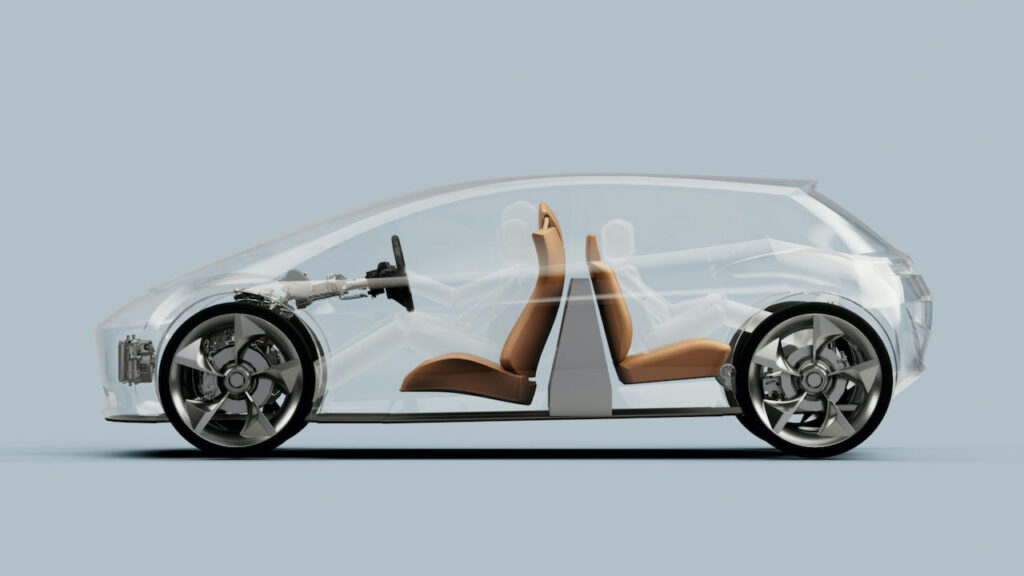

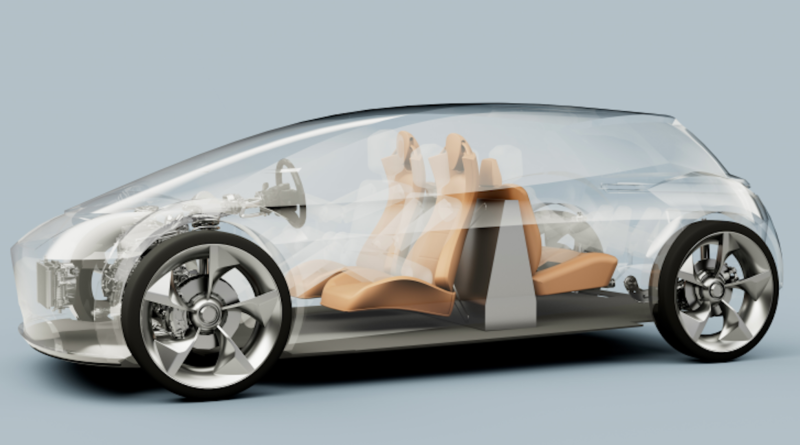

Page-Roberts, established in 2019, has patented an arrangement where batteries are stacked between the first and a rear-facing second row of seats and claims it can add up 30 per cent more range between recharges.

This layout abandons the usual skateboard structure employed by battery electric vehicles – such as Hyundai’s new e-GMP platform – that arranges the packs under the floor.

Page-Roberts argued skateboards add height, weight, body structural complexities and often a longer wheelbase, all to the detriment of range.

“The skateboard arrangement has become the mainstay of most EVs,” said eponymous company CEO Freddy Page-Roberts.

“But this results in taller vehicles with increased aerodynamic losses and energy consumption (especially at motorway speeds), extra structure required to protect against impact, and a longer wheelbase to account for the battery.

“The increased size and weight dramatically inhibit range. By simply moving the location of the battery pack, we have come up with a much more efficient solution.”

Page-Roberts says its unique design would be particularly suited to small EVs and sporting-oriented road cars because it would enable a lower height.

“Challenges around battery cost and energy density along with range and charging infrastructure continue to stall progress with EVs, despite both car brands and tech leaders racing to put their stamp on the market,” said Page-Roberts chief technical officer Mark Simon.

“Our design concept reduces costs, increases efficiency, enhances agility, and offers design freedom. The efficiency translates to less time charging from either longer range or smaller batteries, so pressure on charging points – another key pain point for the industry – will also be reduced.”

While an equivalent-sized battery is claimed to deliver extra range, Page-Roberts also pointed out its vertical arrangements also allows smaller packs to be used to gain equivalent range. This would also save costs.

It also says manufacturing costs could be slashed by up to 36 per cent by its design.