Aussie electro-mod Datsun 1200 ute – 730kg of rapid brilliance

The electro-modding scene in Australia is on one hell of a roll right now, and latest battery-powered marvel to emerge is Ken Macken’s 1981 Datsun 1200 ute.

Known as the Dasla, this tiny single-cab Datto – built and based in Noosa, Queensland – uses a US-sourced NetGain HyPer 9HV motor with AC-X144 inverter, powered by five 5.6kWh Tesla battery modules.

Good for around 90kW and 233Nm, Ken says he’s timed the ute to under 1.5-seconds from 0-50kmh, and it’ll surge on to 100km/h in under six seconds.

How so? Weight. Or lack of it. While modern production EVs are in constant turmoil with mass, Ken’s little electric ute weighs just 15kg more than the original 40-year-old 1171cc version’s svelte 715kg.

As it tips the scales at just 730kg, lots of heavy batteries aren’t needed for useable range. Ken says when he drives conservatively, the converted Datsun achieves roughly 180km on a single charge. Ample for daily jaunts around town.

The popular choice

Many classic car enthusiasts are in two minds about electric conversions, while some are strongly opposed. But Ken’s Datsun is proving there are vast swathes of people who love and respect what he’s achieved.

He’s had numerous offers from those wanting to buy it, others keen on him doing something similar to their car, while it has just won People’s Choice award at the prestigious Roadrunner Car Club Noosa Charity Car Show.

The build quality is excellent. The neatness of integrating the electrical components, the batteries mounted low and not affecting the usability of the ute tub, and the dashboard kept remarkably original. There’s a rotary dial subtly added to select D, R, or N, but the Datsun’s manual gear shifter and gearbox remain.

Incredibly, the project has taken Ken just 11 weeks to complete – including stripping back and restoring the bodywork. But don’t think for a moment this is the norm.

Ken sees himself as a modern-day MacGyver. Not the explosions bit, but that rare ability to seemingly be locked in a shed of machinery for all of 30 minutes then emerge with something bespoke and brilliant.

He’s a multi-award winning inventor who holds a number of patents, and his background includes being a machinist, toolmaker, mechanical engineer and software engineer.

Growing up in Dubbo where “nothing worked,” Ken said his first repair win was on a 50cc Suzuki trike when he was only nine. “I clearly remember that being a turning point,” he said. “Something that was going to be thrown in the trash, I got it working again.”

Rapid restoration

He bought the ute in late June 2021 from the rural Queensland town of Chinchilla. Being 300km inland from Brisbane, cars survive longer out here than in rust-bringing coastal spots.

“It had been spray-painted two-tone orange and blue, done with a fence sprayer,” Ken said. “The body hadn’t been prepped properly. It was pretty bad and needed lots of body work, but it didn’t have the rust.”

Ken took it back to make it what he calls “everyday quality”, that is not concours-perfect, but straight enough. He did all the bodywork himself, while local company Rapid Repairs Paint & Panel did the prime and paint – a lovely retro “K Teal” custom colour.

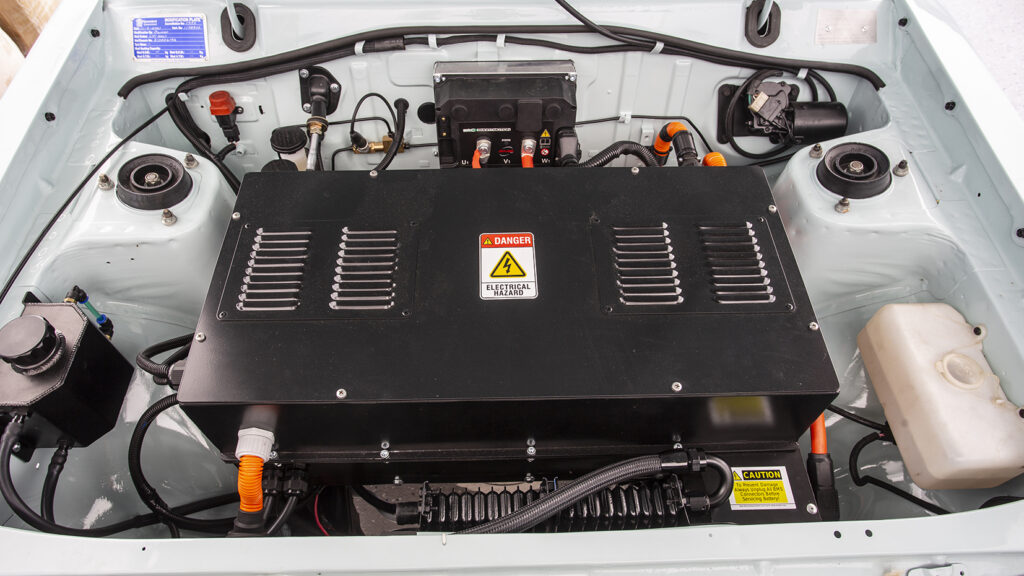

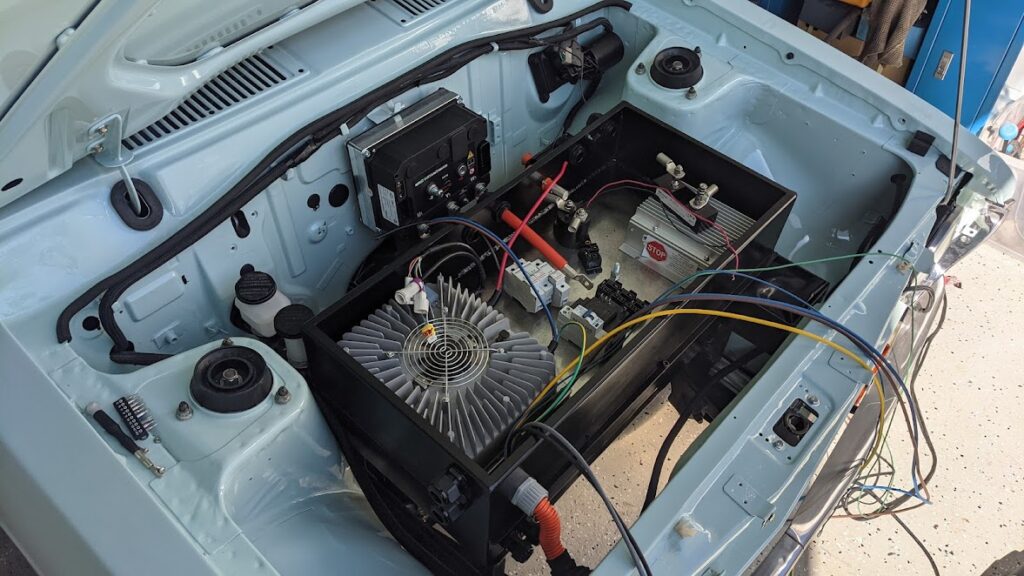

Ken bought the electric conversion components directly from the US and from Australian distributors. We’ve seen the NetGain HyPer9 AC motor in conversions from the likes of Queensland’s Traction EV before, and this 9-inch 54kg motor sits low in the engine bay, below the control components and protective cover.

The motor’s a 144 Volts version, but Ken said the nominal voltage on this setup is 111 Volts. “I use the HyPer9 because the motor controller that comes with it has the built-in pre-charge circuit which is a lot simpler and more robust.”

The motor’s connected to the Datsun’s original gearbox, albeit with a sports clutch added “so it bites a little bit more,” said Ken. “You can just leave it in third gear. If I’m driving at about 80-90km/h I’ll put it into fourth gear as it’s a bit more comfortable to drive.”

Why keep the original transmission? “That configuration: motor to existing flywheel, clutch, gearbox, driveshaft and the same diff; it’s reliable, durable and easy to fix. It gives a good amount of torque transfer out of it, which is a really nice thing.”

It also retains the classic car feel. You can hop in and recognise it as an easy-to-understand interface. “It’s just so much fun to put it into second gear and beat a Ferrari or Lamborghini off the line” said Ken. “In third gear, if you boot it from 10km/h, you’ll beat practically any car.”

Charging at home

On the charging front, Ken uses a Thunderstruck TSM2500 2.5kW on-board charger. An Orion BMS 2 battery management system is the brain of the whole car, dealing with all the charging, discharging and safety.

Batteries were sourced from a wrecked European Tesla Model X, and those five 5.6kWh modules – one in the front, four in the underside rear where the fuel tank used to be – have a working capacity of around 24-25kWh for everyday use.

From empty, Ken said it’ll take about 10 hours to get a full charge from a household socket. “I generally only charge it when I need to, which is every few days and overnight,” he said. There’s regen braking too for a bit of extended life.

The charge port takes a Type 2 plug, and is mounted neatly in the front grille.

The cabin’s incredibly cosy, featuring more modern Nissan seats for comfort. The dash looks neatly original, beyond an integrated audio screen and rotary gear selector.

“I isolated the fuel gauge and temperature gauge and created some new electronics and software to run them,” Ken said. “The fuel gauge now shows the state of charge, and the temperature is the motor inverter temperature that it’s running, which is liquid cooled. The original battery warning light is now the charge light, while my low fuel light comes on when the battery is low on charge.”

We went for a short drive and it is an impressive classic drive experience, albeit without the familiar four-cylinder noise. It’s near silent at low speed, and despite the obvious leap in performance, the chassis seems well-sorted and comfortable in handling the electric power and instant torque. Fun? Bags of it.

Future plans

This being Ken’s first EV conversion, he reckons he’ll be able to complete the next one even faster than the 11 weeks this Datsun took. The project? Hopefully an early 1970s Ford Bronco for electric driving on the beach.

Ken works quickly and smartly due to his obvious talents, learnings and experience. He’s a huge champion of electric conversions for classic cars, but insists it can’t be done on the cheap.

“Its great people want to do this and are inspired to do this, but a lot of people are penny pinching and are putting not just their lives at risk, but others’ too,” he said. “There are many online groups and forums, many people building EVs, who are hacking things together, and that’s a bit scary in terms of safety. It’s not regulated either, which is also scary.”

Ken said if you’re planning a classic EV conversion, speak to an engineer before you even buy the donor car. “If you’re going to do it seriously, an engineer shouldn’t even charge for the consultation. See an engineer first. Get high voltage training. Understand what you can’t do and find the people that can do it.

“If you’re considering doing such a thing, don’t do it cheaply. Don’t buy a cheap BMS. Don’t buy a cheap cable of cheap connectors. Buy real things. They cost hundreds of dollars for a reason.”

Ken said he’s planning to perform EV conversions for customers, and can be reached through his website www.futurepastev.com to discuss potential builds.

He’s positive the electromod future is going to be huge. “The new era of resto EVs will allow classic cars to exist, thrive and increase in value globally. But most importantly, be driven on the roads.”

A great conversion!

So, where are the batteries located? I did a twin cab Datsun conversion in the 90’s, and I had issues with the front being way too light. There’s almost nothing left in this one either, unless they put the batteries in there after that photo was taken.

Hey Bruce. One of the batteries is located up front and low down, the other four under the rear where the fuel tank once was.

With no load in the back of this Datto the front end didn’t feel especially light. Pretty balanced actually.

This being a single cab and weighing only 730kg probably helps…

A fantastic concept, and even though components might be expensive, it might be affordable for those who would love a Tesla but simply don’t have the funds.

I think it would be a great consolation to have your classic, or a donor car converted to EV so that you could enjoy the economy and incredible performance. 😃

Cheers “PonyRider”

“those five 5.6kW modules…have a working capacity of around 24-25kW”

Slight correction, units should be kWh assuming these are capacity numbers rather than power output.

Thanks for pointing that out – we’ve corrected the article.

I don’t want to sound like a nay sayer, as this sounds like an awesome conversion, but I suggest your claimed 1.5s to 50kph is a little …… enthusiastic. This would require an average acceleration of 0.92g. To achieve this, you would need tyres with a coefficient of friction of 1, and almost complete weight transfer to the rear wheels (I didn’t see mention of it being awd). The car would need enough torque at the wheels to lift the front of the car. If you ever did this, you would lose steering control. In drag cars, you need a locked diff so that you don’t tank steer when lifting the front, otherwise you could do an unplanned 90 degree turn.