Radical EV shift! Battery giant CATL says sodium-ion tech will be on sale by late 2025

New generation sodium-ion batteries are only a few months away from a showroom debut – in some parts of the world, at least.

The new battery chemistry promises to lower the price of EVs by significantly reducing the manufacturing cost of the most expensive component of an electric car.

The world’s largest battery manufacturer, CATL, has confirmed the new chemistry will appear in a production car by the end of 2025.

READ MORE: Battery revolution! Has Stellantis cracked the code for super-cheap EVs?

READ MORE: What is a solid state battery?

EV ADVICE: All your questions answered about electric cars

Speaking to EV Central at the recent Shanghai motor show, CATL engineer Jimmy Zhao said the long-awaited tech would be in showrooms within months.

While he would not confirm which model or brand would debut the sodium-ion battery tech, CATL has previously confirmed it is working with Chinese brand Chery.

“Sodium-ion is cheaper than lithium-ion,” said Zhao. “The resource is more plentiful … so the cost will be lower.”

Sodium-ion batteries cheaper to produce

Sodium-ion batteries do without lithium, one of the more expensive minerals currently used in all EV batteries.

The sodium – or salt – ions take the place of lithium-ions in travelling through the battery’s electrolyte from one anode to the other.

It is far cheaper and easier to source, making it ideal for the scale required for EVs.

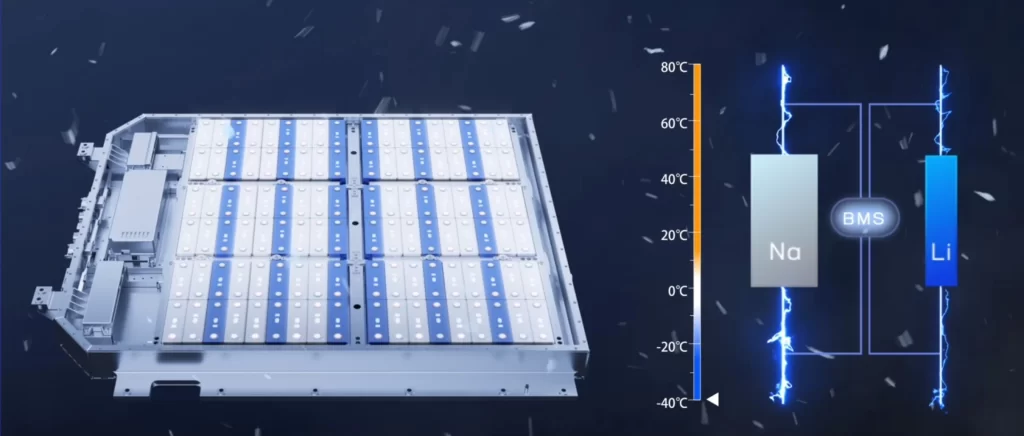

CATL says the technology is also more resilient to low temperature extremes, making them better suited to extreme cold applications such as parts of North America and Europe.

“In minus 40 degrees C the energy retention is 90 per cent,” said Zhao, who added that “the battery can discharge as normal” in extreme cold conditions (EV batteries prefer not to be fully drained in extreme cold).

Sodium-ion batteries to last longer

Sodium-ion batteries are also claimed to be able to have a life of up to 10,000 cycles – around five million kilometres for an EV with 500km of range – which is around three times more than the commonly used NMC (nickel manganese cobalt) batteries.

Sodium-ion battery chemistry would be the third main chemistry available for electric vehicles, although there’s more on the way.

Many brands are working on solid state batteries, which replace a liquid or gel electrolyte with a solid substance, bringing benefits in safety, charging and energy density.

The longest running NMC – nickel manganese cobalt – chemistry is favoured by performance and luxury models and has until recently been the most prolific technology in the ramp up of EV sales.

But in recent years predominantly Chinese manufacturers have favoured LFP – lithium ferrous phosphate – batteries that do without cobalt and nickel.

LFP batteries are typically cheaper to manufacture but hold less energy, making them ideal for shorter range or cheaper EVs.

Tesla, for example, uses LFP batteries on its Rear-Wheel Drive models but NMC batteries for more powerful dual motor versions.

But sodium-ion batteries can’t hold as much electricity

Zhao said sodium-ion batteries have the lowest energy density of the current crop of EV batteries. He said they hold about 175Wh of energy per kilogram, which translates to 285kg for a 50kWh battery.

He said LFP batteries have upwards of 180Wh/kg energy density and NMC upwards of 200Wh/kg. For that same 50kWh battery that means less than 250kg for a 50kWh battery.

That will likely make them appealing for lower cost applications.

“Energy density will be lower than LFP,” he said.

“It can replace some of the LFP batteries, but it cannot totally replace LFP.”

Zhao predicted sodium-ion batteries will be used at the lower end of the market, LFP for the middle of the market and NMC for more expensive and higher performance EVs.

“Some cheaper vehicles like A-class (small) vehicles is more fit for the sodium-ion battery.”