New million-kilometre 50-year Geely battery headed for Australia in 2025 Galaxy E5

Geely Auto has launched its next-generation lithium iron phosphate (LFP) battery technology claiming it is designed to withstand driving one million kilometres over 50 years.

And it could be in Australia soon because the first vehicle it will be fitted to is the new Geely Galaxy E5 SUV that is expected to be on-sale here as soon as 2025.

Currently, most batteries have a useful life of between 10-15 years, with many used buyers put off by the prospect of buying a high-kilometre or aging EV over battery reliability fears.

READ MORE: 2025 Geely Galaxy E5 revealed: Meet the latest electric Chinese Tesla Model Y fighter coming to Australia

READ MORE: China’s Geely launches new electric brand Galaxy

READ MORE: Geely reveals Radar RD6 dual-cab ute, first model from new global EV brand

But according to Geely (owner of Volvo, Polestar, Lotus, Smart, Zeekr and Lynk & Co and many more) its future batteries will end fears over battery durability.

The Aegis Short Blade battery as it is dubbed by the Chinese car giant, is also claimed to lead the class for charging speed and safety.

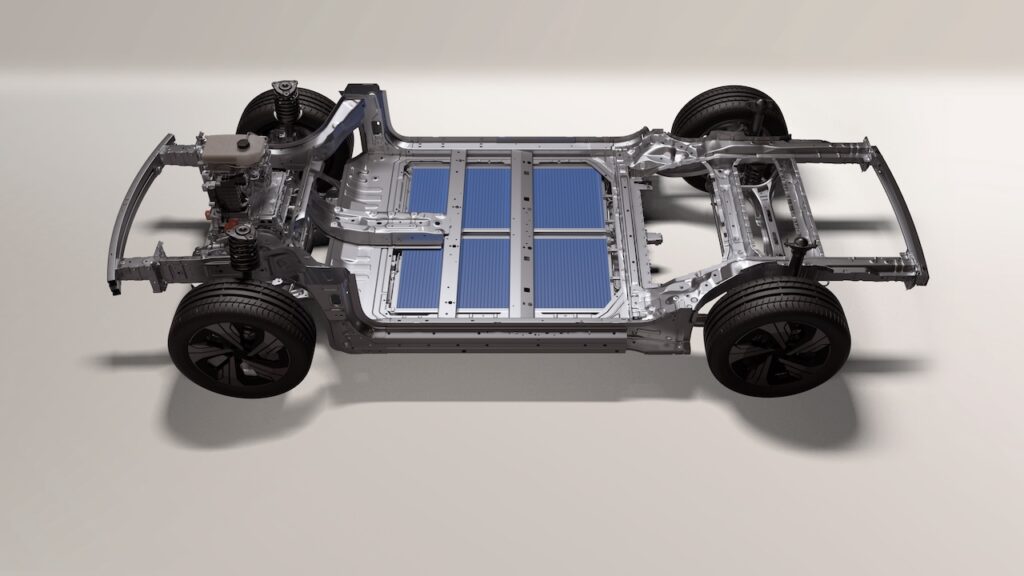

The Geely Galaxy E5 SUV is a Tesla Model Y fighter that makes its debut with the new Short Blade battery in August. It will initially be available as either a 49.5Kwh or 60.2kWh power packs, which will provide the E5 with a range of 440km and 530km under the more lenient Chinese CLTC test regime.

Perhaps more impressive is that combined with the Galaxy brand’s 11-in-1 intelligent drive system, the E5 will have ultra-low energy consumption of just 11.9kWh/100km.

Measuring in at just 580mm long – 40 per cent shorter than traditional batteries, hence its Short Blade name – the new powerpack is said to have a design that generates less internal resistance.

That means the cells generate less heat when in operation, or charging.

Speaking of which, Geely says the new Short Blade is capable of withstanding 3500 charge cycles, which is equivalent to driving one million kilometres, without any significant drop-off in in capacity, or range.

That means if the average driver covers 20,000km a year, owners of next-gen Geelys could theoretically keep their cars for 50 years before needing to seek a replacement.

Geely thinks that with a longer-life battery residual values of its vehicles will be far higher than today with the incentive provided to drive their EV longer before it is scrapped.

The Chinese brand says by doing this carbon emissions could be reduced by 80,000 tonnes a year.

Another highlight of the Short Blade battery is its fast-charging. Thanks to low internal temperatures the Geely battery can be topped up from 10-80 per cent in as little as 17 minutes and four seconds – a significant improvement on the average 26 minutes it takes to top up a traditional battery.

For those who live in cold climates, the Short Blade is claimed to lead the class for range degradation, with the Geely batteries retaining 90.54 per cent of its capacity at -30C – beating average retention rates of 78.96 per cent.

The key to its class-leading performance is long, thin carbon nanotubes within the battery that aid ion transmission that’s boosted further by additives.

All the changes make it easier for the lithium ions to travel between the electrodes.

Safety also has not taken a back seat and the Geely Aegis should be among some of the safety batteries ever made.

As well as immersing the batteries in seawater, the battery pack withstood extreme cold environment testing(-35C), high frequency scraping, a 26-tonne impact, a side collision and being place in a 1000C fire for 130 seconds.

All the tests passed were well above the national standard.

Engineers even punctured the battery with eight five-inch nails without any ill-effect after an hour.

Finally, Geely fired a standard issue 5.8mm Chinese army rifle round into the battery and recorded no thermal event.

The secret to the Short Blade’s enhanced safety is its “high-strength high-thermal stability height heat resistant diaphragm and a highly stable separator, plus ‘safe electrodes’ that all contribute to improved energy density and safety.

The battery also has a self-healing capability thanks to clever tech that sees an aluminium foil layer fuse over puncture holes, or damaged areas, providing an insulating layer.

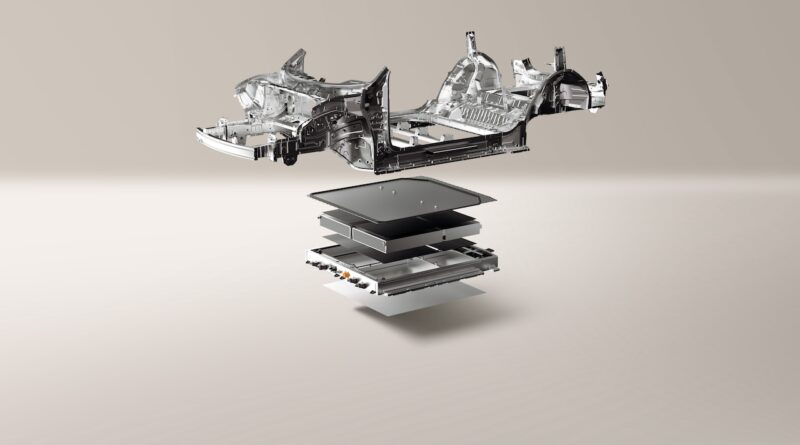

Other safety aids include a robust grid frame design, energy-absorbing cavity, three-layer sandwich bottom guard plate, cell-to-body integration and a thermal runaway control system, plus other safety features related to the software governing the cells operation.