Nissan to replace Micra mini car with all-new EV

Nissan says it plans to produce an affordable mini EV, possibly as early as 2024. It will replace the Micra, the brand’s long-serving city car, sold in Australia from 1995 to 1997 and again from 2007 to 2016.

Though designed by Nissan, the all-new EV will be built on the same Renault-engineered platform as the R5 EV and manufactured in the same Renault plant in the north of France.

READ MORE: Nissan previews next Leaf, reveals $25b EV commitment

READ MORE: Nissan’s global EV ramp up leaving Australia behind, Ariya now 2023

READ MORE: 10 EVs by 2025, axial flux motors and fresh tech for Renault

It’s a case of “maximising the use of our Alliance assets,” said Nissan chief operating officer Ashwani Gupta, “while maintaining its Nissan-ness”.

Renault promises the R5 EV’s new CMF-BEV platform, the basis for the Micra replacement, will be “the most competitive compact electric platform in the world”. It will deliver a driving range of up to 400km at the same time as reductions of 33 percent in cost and 10 percent in energy consumption compared to the current Renault Zoe, the company says.

The Renault R5 EV opens the short Nissan Micra replacement teaser video. Here’s the link or you click on the play button below.

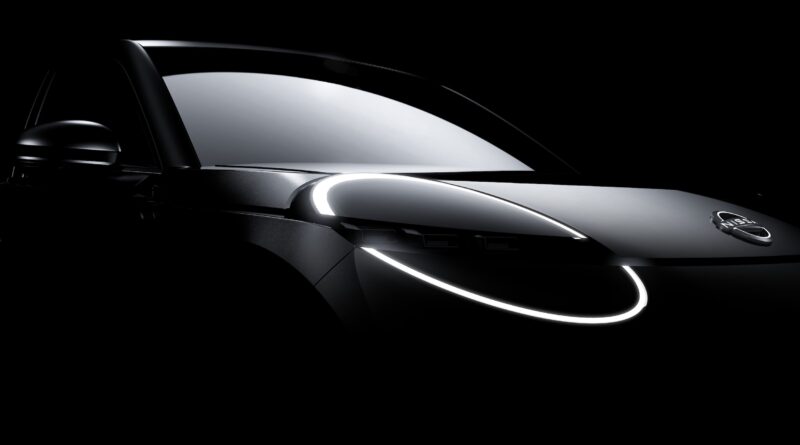

We’ve also screenshotted some of the Micra glimpses from the video so you can get a better idea of what the crucial new Nissan compact EV looks like.

Production of the R5 EV will begin in 2024. Its Nissan-badged assembly-line sister can be expected to follow shortly afterwards. From an Australian perspective, the only problem is that Nissan says its Micra successor EV is aimed at European markets.

Nissan’s announcement was part of the Renault-Nissan-Mitsubishi Alliance 2030 roadmap outlined overnight. The auto-industry giant plans to invest $37 billion in electrification in the next five years. The Alliance’s objective is to have 35 new EVs on sale by 2030, more than any of its competitors.

Under the Alliance 2030 roadmap, each member will work on technologies for use by the entire group.

Nissan is specifically tasked with leading a solid-state battery development program. These, it’s hoped. will have double the energy density of current liquid-electrolyte lithium-ion batteries, and take one-third as long to recharge.

Once solid-state production is under way – 2028 is the target – Nissan will focus on reducing the cost of the cells. They’re shooting for US$65 for a kilowatt-hour (kWh) of battery capacity, about half the cost today and enough to bring EVs to price parity with ICE-powered vehicles.

While waiting for solid-state tech to be developed, the Alliance has set cost-reduction targets for existing lithium-ion batteries; 50 percent by 2026 and 65 percent by 2028.