Why are electric cars so expensive?

Batteries, basically….

Electric vehicles are much more efficient than fuel-burners, but they still require lots of energy. Batteries, which must be big and heavy to give an EV a good driving range, do the job … but at a high price.

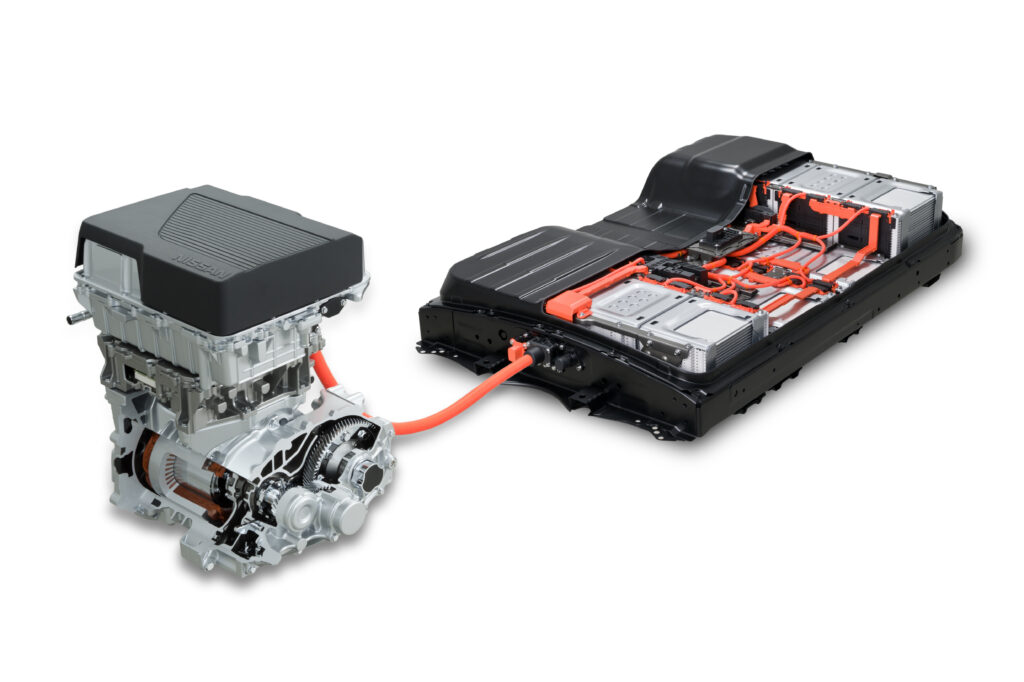

Many hundreds or even thousands of individual battery cells are packed together into tens of modules, which are the basic building blocks of a battery pack.

Want the latest EV news and reviews delivered to your inbox? Subscribe to our weekly newsletter!

In a typical EV the battery pack will be up to a couple of metres long, more than a metre wide, between 10cm and 20cm thick, and weigh hundreds of kilograms.

While the electric motors in EVs, and their transmissions, are relatively simple and inexpensive, lithium-ion battery cells are costly.

READ MORE: 2021 EV running costs anaylsis: Complete guide to the price of buying and running an electric car

READ MORE: See all our FAQ, tips and advice on electric cars

READ MORE: Do EV batteries wear out?

READ MORE: Do EVs require servicing?

READ MORE: How much do EVs cost to run?

Install a lithium-ion power bank in your house and you’ll typically pay something like $800-$1000 per kilowatt-hour of battery capacity.

When you consider that a modern electric car usually has a battery capacity between 40kWh and 100kWh you can see the problem.

Those prices are at retail level and car makers pay much less, but auto industry executives say the current price of battery packs is still around $200 per kWh, or more.

Expensive but essential metals, such as cobalt, are one of the factors that make batteries so costly.

Cobalt is currently used in almost all lithium-ion batteries used in EVs and hybrids, although General Motors says it will soon eliminate it from its batteries, making them more affordable. Tesla chief Elon Musk has also said it is working on next-generation batteries that will not use cobalt.

Batteries also require sophisticated sensors and software to control cell voltage, charge and discharge rates, and temperature.

This complexity adds yet more cost.

It doesn’t help, either, that EVs are produced in relatively small numbers by mass manufacturing standards.

Building more of anything makes it cheaper. The costs of design, development and manufacturing machinery are fixed, no matter how many units are made. Produce more and the per-unit price falls. Buying materials and components in bulk is usually cheaper, too.

As cell production increases, battery pack prices will naturally fall further, as they have done since 2010.

But the use of expensive metals also limits how cheaply they can be produced.

Major vehicle manufacturers and battery suppliers such as LG Chem, Samsung SDI and Panasonic, along with less well-known names likes CATL, are constantly working on ways to make lithium-ion batteries more affordable.

They’re also working on new battery technologies, including solid state lithium-ion batteries that so far can’t produced affordably or safely in commercial quantities.