Nissan’s Aussie battery recycling solution: LEAF batteries become second-life power packs at Melbourne factory

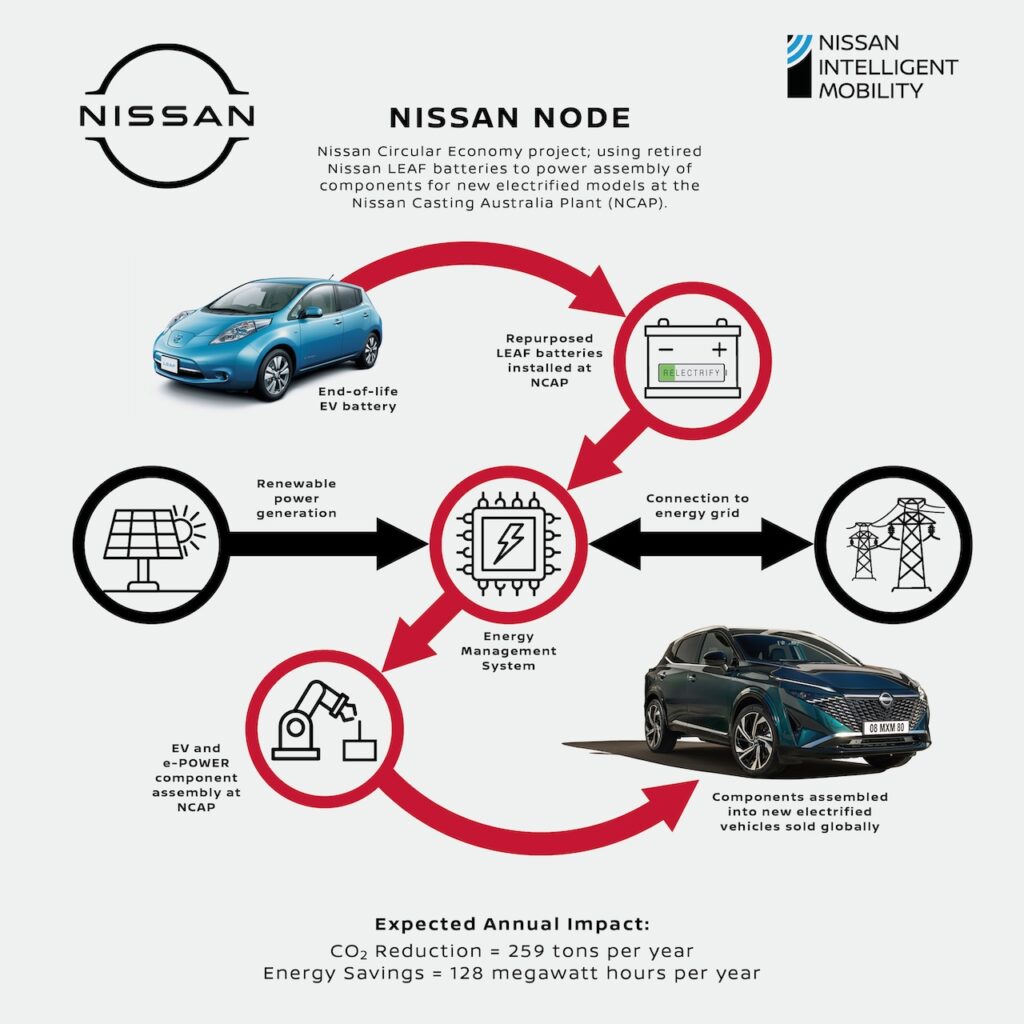

Nissan Australia has announced a pioneering initiative that will see old batteries recovered from recycled Nissan Leaf hatchbacks go on to help power part of its casting plant in Dandenong.

The new plan will see repurposed powerpacks work with a solar farm that has been recently built nearby the Nissan Casting Australia Plant (NCAP) in Dandenong, Victoria.

Using as many as nine power packs from the first-generation Nissan Leaf (2011-2017), which first went on sale Down Under in 2012, the renewable energy storage devices will be used as part of the production of components at the factory, as well as helping supply electricity to charge staff vehicles on site.

READ MORE: Nissan Frontier Pro coming to Australia: Plug-in hybrid ute will fight the BYD Shark 6 and lead a China-sourced electric new model attack

READ MORE: Why the Nissan Ariya is a great buy … in 2030: Our hit-list of the EV bargains you need to start saving for (but only a little bit)

READ MORE: 2026 Nissan Qashqai to go hybrid only as it chases down Toyota, Hyundai small SUV with upgraded e-Power system

Once up and running the nine Leaf batteries will help Nissan Casting Australia slash its annual CO2 emissions by 259 tonnes per year, while saving an estimated 128 megawatts of energy that would normally be drawn from the grid.

First established back in 1982, Nissan’s NCAP facility dedicates around 50 per cent of its output to producing high quality aluminium castings that are then used in Nissan’s battery electric and hybrid vehicles that are sold globally.

Every Nissan Leaf EV sold globally to date has had components fitted that were manufactured in Australia, as well as vehicles that feature the brand’s e-Power hybrid tech, including the latest Qashqai e-Power.

To help re-use old Leaf batteries locally, Nissan Australia said it teamed up Melbourne-based The Node Project that has developed what’s claimed to be ‘groundbreaking’ techniques to manage batteries.

It also claims new inverter tech that dramatically extends the life of batteries that enables them to be repurposed as second-life batteries.

Commenting on the CO2-saving initiative, Nissan Oceania Managing director, Andrew Humberstone said: “This isn’t just a hugely exciting project, but an important step into the future for end-of-life EV batteries.

“As an early pioneer of the electric vehicle both globally and locally, we can also demonstrate leadership in second-life battery initiatives.”